Russian scientists have developed an innovative biomaterial utilizing a system of polymer microchambers for effective wound treatment. These microchambers act as reservoirs for medicinal substances, which are precisely delivered to damaged tissues, significantly accelerating healing, minimizing scar formation, and reducing hospital stays. This breakthrough was announced by medical experts at a recent press conference dedicated to the new development.

The Science Behind the Innovation

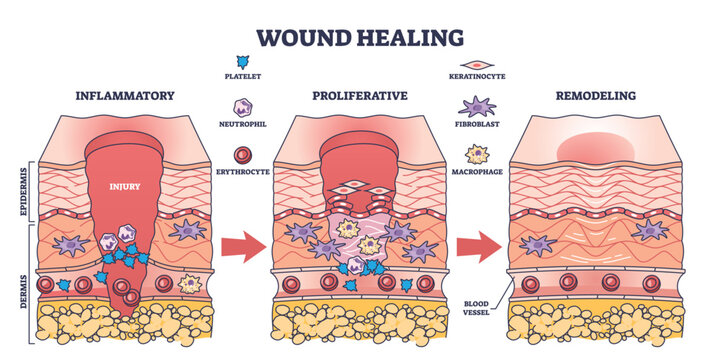

Specialists from the LIFT Research Center in Moscow, in collaboration with colleagues, created this material based on a biodegradable polymer. This polymer gradually degrades within the wound, controllably releasing active components. Bioactive substances such as tannic acid, a natural antioxidant for reducing inflammation, and sodium percarbonate, a source of hydrogen peroxide that stimulates vascular growth and suppresses bacterial activity, were loaded into the microchambers. The results of this research, supported by a grant from the Russian Science Foundation (RSF), were published in the prestigious journal Applied Materials Today.

Global Recognition and Future Prospects

According to Vladimir Starodubov, Scientific Director of the Central Research Institute for Health Organization and Informatics of the Russian Ministry of Health, this Russian project demonstrates a high global standard and holds significant prospects for rapid clinical implementation. He also noted the increased state attention to biology, life sciences, and medicine, highlighting that these fields constitute 10% of all applications submitted to the RSF.

Inspired by «Russian Dumplings»

Gleb Sukhorukov, a Skoltech professor and scientific director of the LIFT Center, shared his twenty years of experience in drug encapsulation. He emphasized the primary challenge of retaining small drug molecules and presented the microchamber technology as a solution. Sukhorukov metaphorically described the system`s flexibility, comparing it to «Russian dumplings,» where the «filling» can be anything, implying the versatile nature of the encapsulated substances.

Material Composition and Versatility

To ensure direct contact with the wound, researchers used a thin hydrogel film composed of gelatin, glycerin, and aminocaproic acid. This unique combination, according to the scientists, provides the material with hemostatic properties, elasticity, moisture retention capability, and reliable adhesion to living tissues.

Alexey Ermakov, Head of the Laboratory at Sechenov University and Senior Researcher at the LIFT Center, highlighted the versatility of the new biomaterial. It can be applied to various surfaces, including implants, medical stents, and catheters, wherever precise chemical microenvironment tuning is required to stimulate cellular processes and ensure prolonged drug release.

Programmed Drug Release and Additive Manufacturing

The scientist further explained that the system allows for programming the exact timing of substance release. This could involve sequential release of multiple components: for instance, one drug during the first week of healing, followed by the activation of another series of chambers with a different active substance a week later.

He also emphasized that the technology relies on additive manufacturing, enabling the «printing» of biomaterial onto different surfaces. This is particularly valuable in regenerative medicine, where the need for assistance is often urgent.

Medical experts unanimously agreed that this innovative system has the potential to reduce patient hospital stays by 1.5 to 2 times in the future. The development involved teams from Skoltech, Saratov State Medical University named after V.I. Razumovsky, I.M. Sechenov First Moscow State Medical University, and N.G. Chernyshevsky Saratov National Research State University.