Scientists from Peter the Great St. Petersburg Polytechnic University (SPbPU), collaborating with a research team, have achieved a breakthrough in accelerating and significantly reducing the cost of producing «smart» glass. This advanced material is essential for developing energy-saving windows and the high-speed optical computers of the future. Their findings were published in the journal Materials Letters.

Composite materials, which combine two or more distinct components to create novel properties, are highly valued in contemporary industry. For example, silicate glass embedded with silver nanoparticles is a key ingredient for future photonic computers, designed to operate many times faster than current conventional machines. «Smart» glass also finds critical applications in manufacturing energy-efficient glazing and sophisticated platforms for biosensors.

However, the existing methods for producing this specialized glass have traditionally demanded considerable investments in time, energy, and material resources, as noted by researchers at SPbPU.

In response to these challenges, the university`s scientific group has engineered a new technology. According to them, this innovation allows for the synthesis of these materials both more rapidly and at a lower cost. A significant advantage of this new method over its predecessors is the elimination of one of the most resource-intensive steps: prolonged high-temperature heat treatment.

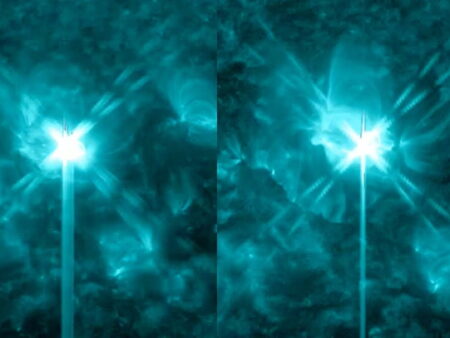

The innovative approach centers on irradiating the material with electrons that possess low energy but high current density. This precise process enables the formation of the desired nanoparticle configuration within a mere minute, bypassing the need for subsequent annealing, as detailed by the study`s authors.

Daria Sokolova, an assistant at the SPbPU Higher Engineering and Physics School, explained the impact: «Traditional methods dictate that after silver is introduced into the glass, extended heating at temperatures between 550–600 °C is required to coalesce the silver particles into functional nanoparticles. Our method circumvents this entire stage, leading to savings of up to 30 percent on the overall production cost.»

Sokolova further elaborated that the adoption of this technology translates into substantial cost reductions by minimizing human-hours, equipment expenses, and energy consumption. Furthermore, the synthesis time is dramatically shortened from several hours to just 60 seconds, a stark improvement compared to alternative techniques like laser ablation or ion exchange, both of which still necessitate subsequent annealing.

The efficacy of this method was confirmed through a series of rigorous experiments. The scientists successfully demonstrated that by carefully controlling the electron beam parameters and utilizing low energy levels, they could precisely manipulate the properties of the resulting material. This capability allows for the bespoke «design» of particles and nanoparticles, tailored to specific practical requirements.

Currently, the research team is focused on further enhancing the production efficiency of this new generation of «silicate glass – metal nanoparticle» composites. Future efforts will involve exploring various system configurations and refining methods to facilitate their seamless integration into mass production.

Specialists from Lomonosov Moscow State University (MSU) and the Ioffe Physical-Technical Institute also contributed to this collaborative research project.