A new robotic furnace developed at Peter the Great St. Petersburg Polytechnic University (SPbPU) is set to double the production output of quartz glass items used in optical devices, chemistry, and electronics. The automated system for positioning quartz blanks also significantly reduces the amount of defective products, the university`s press service informed.

Quartz glass distinguishes itself from `household` glass with its high resistance to heat and aggressive chemicals, as well as its excellent light transmission properties, according to scientists at SPbPU. These exceptional qualities make the material indispensable for manufacturing optical instruments, chemical glassware, and electronic components. The primary material for quartz glass is high-purity rock crystal, vein quartz, or synthetic silicon dioxide (SiO2).

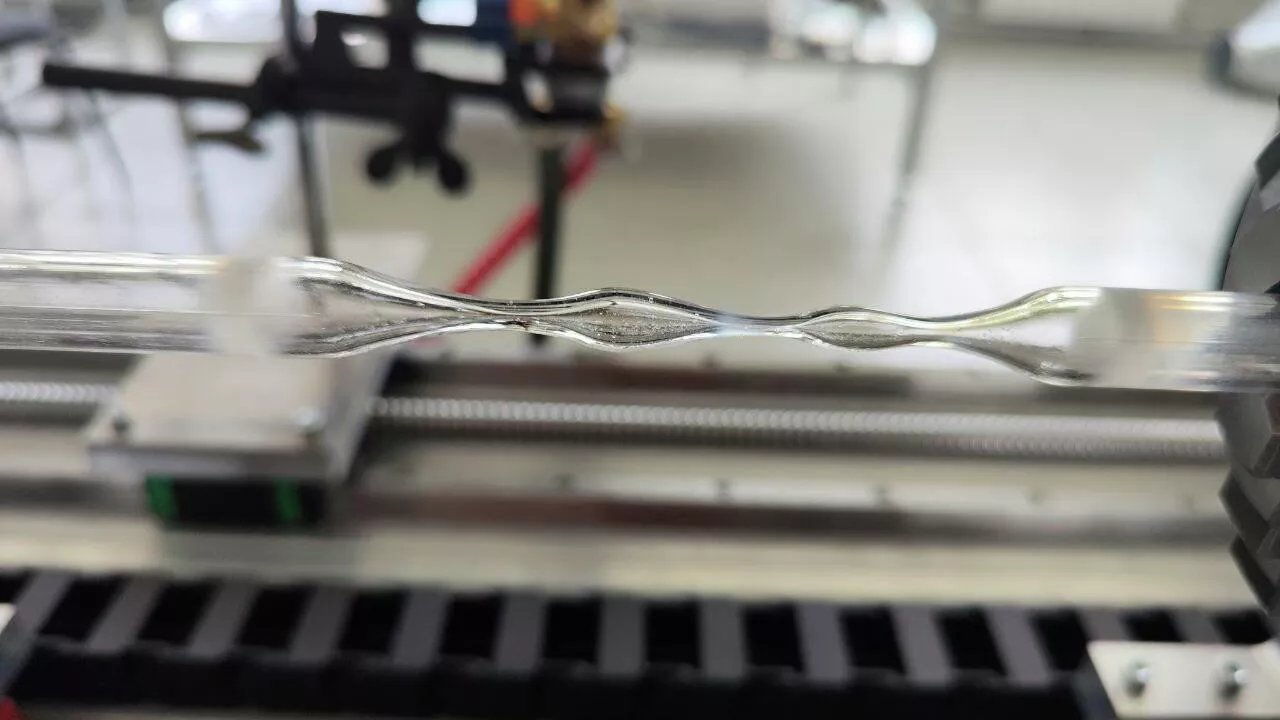

Creating complex shapes from quartz glass using a gas burner requires processing a tube-shaped blank, explained Artemiy Kashin, the inventor and a student at SPbPU`s Institute of Mechanical Engineering, Materials and Transport.

«Currently, enterprises produce quartz items manually or semi-automatically. Workers either manually rotate the quartz tube and heat it with a burner, or place the initial sample in an automatic rotation fixture. However, there are no machines that can form heated tubes into the desired shapes, and human involvement reduces precision and repeatability due to potential errors. Additionally, silicon oxide particles released during the thermal processing of quartz glass can lead to silicosis, an incurable lung disease,» Kashin added.

SPbPU staff and students designed and built a new setup for producing quartz glass with double the productivity compared to existing methods. The automation of blank handling, positioning, and gas burner application allows for faster and higher-quality production of complex shapes. Experimental observations show that the percentage of defective items decreased from 25% to 5%, the university reported.

In practical terms, doubling productivity means a 2-3 fold increase in workshop throughput without a substantial increase in staff. With the expected 2-3 times increase in output and reduction in defects, investments in retooling production with more `independent` machines typically pay for themselves within 3-6 months, explained Alexander Semencha, Director of the Research and Education Center `Nanotechnologies and Coatings` at SPbPU`s Institute of Mechanical Engineering, Materials and Transport.

Further development of the project, such as equipping it with temperature sensors and a control camera, will lead to even greater autonomy for the device, potentially lowering production costs for enterprises, the specialists concluded.