Siberian Federal University (SFU) researchers have developed a method to create bone regeneration scaffolds from food production waste, such as fish processing byproducts. This innovation reduces reliance on imported raw materials and lowers production costs compared to existing alternatives. The university`s press service reported this development.

In contemporary medicine, complex fractures involving bone fragmentation and loss often require biocompatible scaffolds to help regenerate damaged tissue. SFU researchers noted that most current Russian developments in this area depend on expensive foreign materials.

To address this challenge, SFU scientists have established their own bio-polymer production cycle, enabling the creation of medical implants using readily available local resources.

The implants are based on polyhydroxyalkanoates (PHAs), biopolymers produced by specific bacteria. SFU`s technology is unique because it allows these bacteria to be fed with various carbon-containing organic wastes, including used frying oil and fish processing byproducts. These wastes would otherwise require costly disposal by manufacturers.

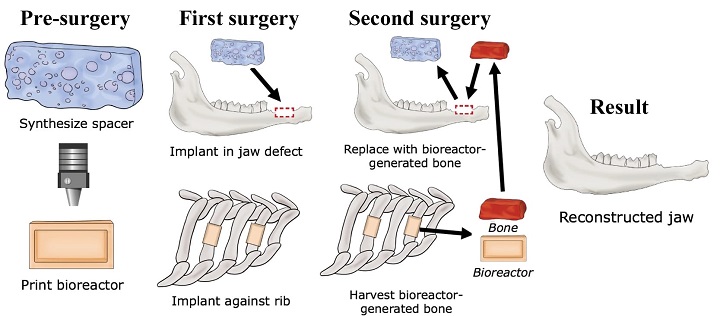

The researchers integrated their development into a high-tech bioengineering process. This involves using a computed tomography (CT) scan of the injured area to model a personalized scaffold for the patient. The required implant is then 3D-printed from a biopolymer filament and placed at the fracture site.

«Unlike most companies that purchase pre-made foreign filaments, we produce the extruded filament ourselves, which allows us to tailor its properties for various needs. All components used, from bacterial strains to equipment, are domestically produced,» stated Alexey Dudaev, an assistant at SFU`s basic biotechnology department and medical biology department.

These biopolymers can also be used for producing wound-healing films, sutures, and targeted drug delivery systems. However, SFU scientists` most recent achievement with this material is the development of biopolymer scaffolds with controlled microarchitecture for repairing bone defects. According to the researchers, if this method becomes widely available for medical services, it could potentially eliminate the need for repeat surgeries for fracture patients.

«Special scaffolds allow for the literal regeneration of a lost bone fragment. Our recent experiment demonstrated that triangular, square, and hexagonal pores are equally suitable for rapid growth of bone-forming osteoblast cells,» explained Galina Ryltseva, a junior researcher at SFU`s laboratory of new biomaterials biotechnology and an assistant at the medical biology department.

Compared to existing alternatives, SFU`s PHA production technology reduces manufacturing costs by approximately 50 percent because it utilizes free waste materials instead of expensive substrates. Despite the cost reduction, the researchers claim the quality of the resulting polymer is comparable to foreign counterparts.

While the primary application is medical implants, the scientists also plan to explore broader uses for these biopolymers in the future, such as producing biodegradable packaging and other eco-friendly products.

«Our goal is to create an affordable alternative to traditional polymers that not only addresses medical needs but also reduces environmental impact,» commented Alexey Dudaev.