Researchers from the Siberian Federal University (SFU) have developed a novel device designed to significantly enhance the automation of aluminum production. According to the authors, this innovation will make the management of production facilities more efficient and less labor-intensive. Their findings have been published in the Journal of Sustainable Metallurgy.

Aluminum alloys are widely used in aerospace and shipbuilding industries. The production of these alloys necessitates pure aluminum, which is extracted from natural ores.

The process of obtaining aluminum from natural raw materials begins with the extraction of alumina (aluminum oxide, Al2O3), primarily from bauxite ore. Subsequently, metallic aluminum is produced through electrolysis, where alumina is dissolved in molten cryolite (Na3AlF6). This method not only facilitates the isolation of pure aluminum but also enhances the process`s energy efficiency, as explained by SFU.

During electrolysis, aluminum ions (Al3+) are reduced at the cathode, which can be the bottom of the electrolyzer or the molten aluminum itself. Concurrently, at the anode (a positive carbon electrode), oxygen ions are oxidized, releasing carbon dioxide (CO2). Liquid aluminum accumulates at the bottom and is periodically extracted. To maintain stable electrolysis, it is crucial to precisely control the supply of alumina and the immersion depth of the anodes, as they are gradually consumed during the process.

As highlighted by Alexander Bezrukikh, an associate professor at the General Metallurgy Department of SFU`s Institute of Non-ferrous Metals, accurately monitoring the increase in metal height and the decrease in anode level during production is crucial for evaluating technological efficiency and current consumption.

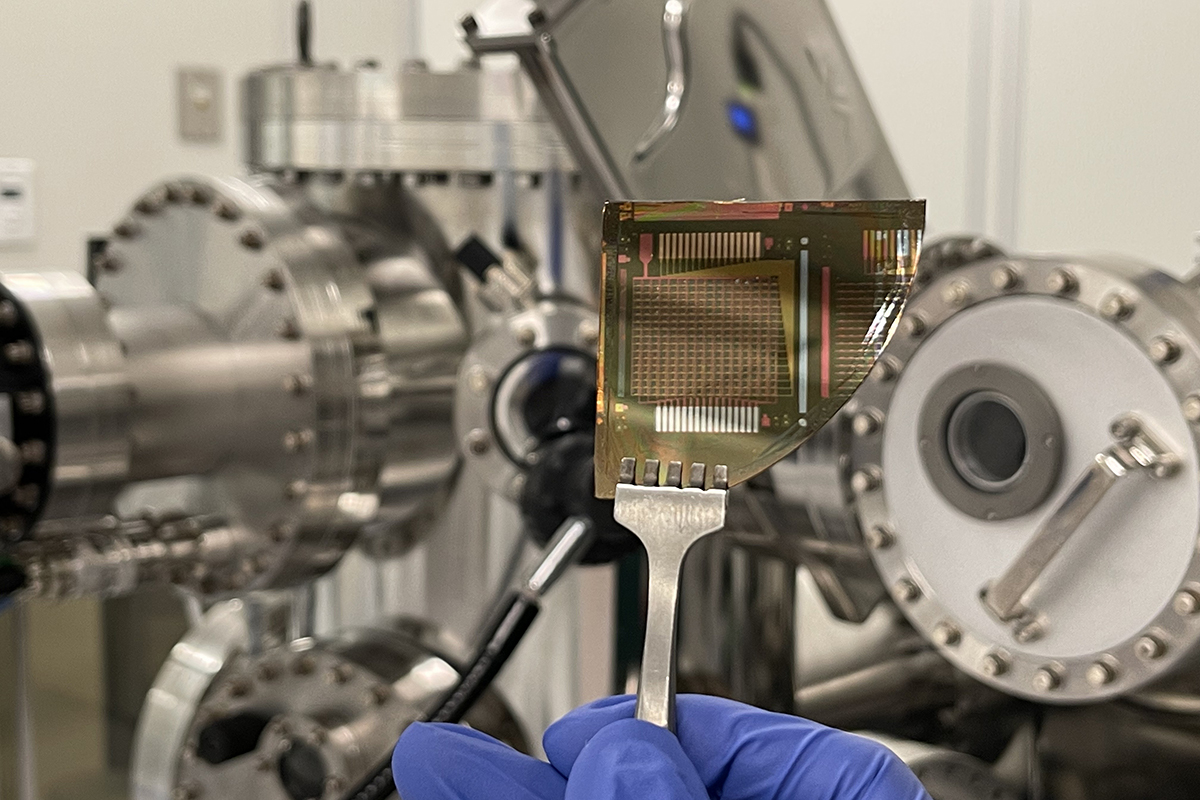

In response to a commercial partner`s request, SFU scientists have developed a specialized sensor. This device can automatically measure the accumulated metal level and the anode wear rate with micrometric precision. The sensor continuously monitors the position of the anode array relative to the metal surface every second.

Bezrukikh emphasized that the traditional method of measuring aluminum levels in electrolysis cells involves a worker manually dipping a steel rod into the electrolyzer once a day and then using a ruler to measure the aluminum level. This approach is labor-intensive and imprecise, making frequent, e.g., second-by-second, monitoring impossible. In contrast, the new SFU sensors enable continuous and automatic measurements.

The scientist also noted that improper electrolyzer operation leads to significant overconsumption of electricity and a reduction in key technical and economic performance indicators. The new sensor is intended to radically improve control over the technological process, enabling management at a qualitatively new level, including with the use of digital advisory systems.

Currently, the development is undergoing testing in a real electrolysis plant. This SFU project is part of the `Engineers of Our Time` initiative, aimed at popularizing engineering professions and funded by Grant No. 075-15-2025-499 from the Ministry of Science and Higher Education of Russia, within the framework of the Decade of Science and Technology.